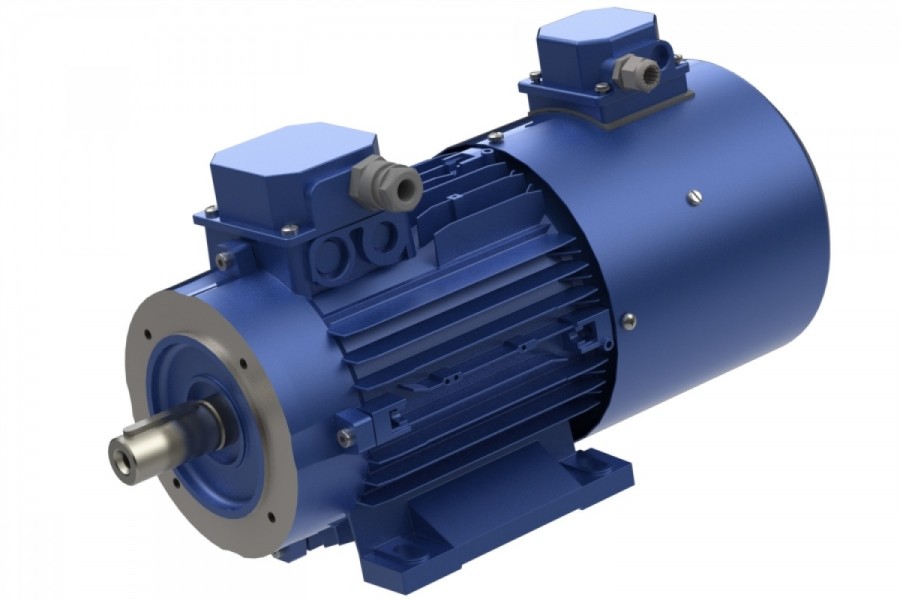

MOTORS WITH FORCED VENTILATION

Unlike fixed speed applications, variable speed applications require motors with improved cooling at low speeds. This is especially relevant for the inverter-driven lifting and traveling motors. In addition to motor speeds close to zero (high torque requirement), forced ventilation is also preferred for speeds above the synchronous ones, where fan noise must be reduced. Our forced ventilated series ranges from frame size 63 up to 160.

These motors are designed to work with inverters. In the territory of the EU the efficiency level of these motors should be at least IE2 according to EN 60034-30. Inverter duty class is always marked on the nameplate.

The speed regulation of the motors is done in 2 ranges:

-n1-nN the change of the speed of rotation of the shaft is done at a constant torque. Frequency of the basic supply voltage deviates from 5Hz up to 50Hz. The power of the shaft increased from PMIN to PN.

-nN-nMAX the change of the speed of rotation is done at a constant power of the shaft. The motor torque decreases proportionally to the speed of the shaft.

-Ration between the maximum torque and nominal torque remains the same no matter of the rotation speed changes.

These motors are cooled by forced ventilation mounted on the rear end shield. Forced ventilation is run by a three phase motor supplied by the network. The winding endings of the auxiliary motor can be placed in a separate terminal box or together with the endings of the main motor in a bigger terminal box.

Motors with forced ventilation are produced with higher isolation.

VSDs: We offer complete drive solutions including high-quality inverters. The speed of rotation, torque and output power can be regulated. Thus, the complete efficiency of the unit is improved. This has beneficial effect on compressors, fans, blowers and other machinery where the complete drive unit finds its application.